SabrToothSqrl

Well-known member

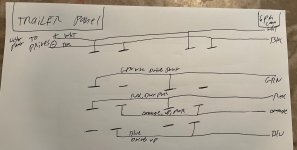

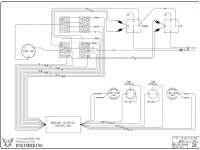

the plot thickens. There is only 1 RD/PR on the wiring diagram. Not 2.

Knowing they are connected elsewhere, I'm wondering if they wired #2 for the second switch, even though it's rather pointless to do it that way.

the Red wire (not on diagram) lets you move the drives down, but not up. However the way formula wired it, negates this, and powers the upside anyway... on the trailer switch. It doesn't seem conditional.

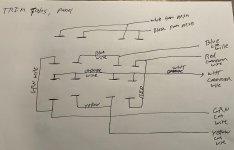

HOW can Green/White come from BOTH switches? How does the unit know which drive I want to go down?!

Knowing they are connected elsewhere, I'm wondering if they wired #2 for the second switch, even though it's rather pointless to do it that way.

the Red wire (not on diagram) lets you move the drives down, but not up. However the way formula wired it, negates this, and powers the upside anyway... on the trailer switch. It doesn't seem conditional.

HOW can Green/White come from BOTH switches? How does the unit know which drive I want to go down?!

Last edited: