Hi, below you will see a very very short version of what you will see if you visit Formula and take the factory tour. I apologize for not having detailed descriptions of what model boats are in the pics, but its very hard for me to remember whats what now that i am looking at the pictures.

If you wish to reply to this post, please do not use the quote option. Enjoy ;D

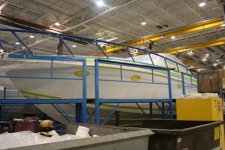

Here you see the hull molds for a few models and then gelcoat being applied.

If you wish to reply to this post, please do not use the quote option. Enjoy ;D

Here you see the hull molds for a few models and then gelcoat being applied.