AllDodge

Well-known member

Don't see any issue with the way your fuel pump is running. The ECM (which is a MEFI-1) turns the VST high pressure pump on for a couple seconds when key is first turned ON. It does this buy appling a ground to the fuel pump relay. Once the engine starts cranking or starts the ECM turns the pump ON again and keeps it going until the key is turned OFF.

Does appear your issue is in the high fuel pressure area. Fuel pressure should be at 37 psi while running. With you being able to turn the key OFF and the pressure stays up, tells me your injectors are not leaking, nor is the regulator. The lower then normal pressure can be caused by the fuel pump or fuel regulator.

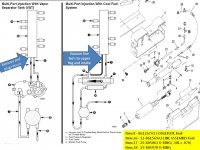

I would start with removing and cleaning the regulator (item 18, p/n 805227A1).

http://www.mercruiserparts.com/bam/subassembly/31810/2336/10

http://www.mercruiserparts.com/805227a1-regulator-kit

It can be checked by applying regulated air pressure to the inlet, and see when the Reg opens

Does appear your issue is in the high fuel pressure area. Fuel pressure should be at 37 psi while running. With you being able to turn the key OFF and the pressure stays up, tells me your injectors are not leaking, nor is the regulator. The lower then normal pressure can be caused by the fuel pump or fuel regulator.

I would start with removing and cleaning the regulator (item 18, p/n 805227A1).

http://www.mercruiserparts.com/bam/subassembly/31810/2336/10

http://www.mercruiserparts.com/805227a1-regulator-kit

It can be checked by applying regulated air pressure to the inlet, and see when the Reg opens

Attachments

Last edited: