Hello Everyone,

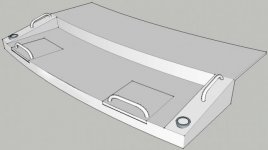

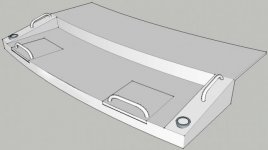

I am taking on a rather ambitious project in making an extended swim platform (a La DIY) for my 1996 330 SS, similar to the factory Extended Swim Platforms that Formula puts on their boats (as an option), like what you see below . . .

Adding an extended swim platform has been on my bucket list for a while, and because I don't know any better , I decided to make one. I have worked up a design that has a couple extra goodies, namely dual fold-out swim ladders, similar to the OEM fold-out on my 330 SS, as well as pop-out cleats for a stern anchor when doing the sandbar thing.

, I decided to make one. I have worked up a design that has a couple extra goodies, namely dual fold-out swim ladders, similar to the OEM fold-out on my 330 SS, as well as pop-out cleats for a stern anchor when doing the sandbar thing.

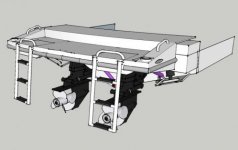

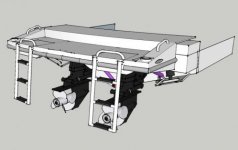

Here is an enhanced design image showing part of the stern area and the ladders deployed.

I've already started making the platform, and not getting into the details, but one question I have is for the folks here with factory provided extended platforms, do you have any photos of how the platform is attached to the stern/transom of the boat? The pictures that I can find online all show the topside of the platform, but I have yet to find any of the underside showing the hardware mounting, struts, etc.

Anyone with the extended platform got any pictures of underneath? @BoilerDaddy - any factory photos that you can share?

I have got some ideas on how I plan to secure the platform once it is made, just looking for some factory comparisons as a sanity check. T. I. A.

I am taking on a rather ambitious project in making an extended swim platform (a La DIY) for my 1996 330 SS, similar to the factory Extended Swim Platforms that Formula puts on their boats (as an option), like what you see below . . .

Adding an extended swim platform has been on my bucket list for a while, and because I don't know any better

Here is an enhanced design image showing part of the stern area and the ladders deployed.

I've already started making the platform, and not getting into the details, but one question I have is for the folks here with factory provided extended platforms, do you have any photos of how the platform is attached to the stern/transom of the boat? The pictures that I can find online all show the topside of the platform, but I have yet to find any of the underside showing the hardware mounting, struts, etc.

Anyone with the extended platform got any pictures of underneath? @BoilerDaddy - any factory photos that you can share?

I have got some ideas on how I plan to secure the platform once it is made, just looking for some factory comparisons as a sanity check. T. I. A.